With a profivac central vacuum cleaner, you have an excellently crafted quality product from Switzerland that will bring you joy and relief for a long time without requiring significant maintenance effort. From a filter system without follow-up costs to high-quality bypass motor technology, the profivac vacuum cleaner system will accompany you for at least the next 30 years.

How does a central vacuum cleaner work?

The motor is the heart of the vacuum cleaner system. It ensures that the air inside the central vacuum cleaner is brought into rotation, creating a powerful vacuum. At speeds of more than 100 km/h, the sucked-in air is shot into the cylindrical cyclone filter chamber. Due to the rapid rotating motion, the particles contained in the air are pressed against the inner walls, where they are guided in a circular motion down to the dirt tank. Even heavy dirt is efficiently separated through the cyclone principle. The dust is collected in the dirt tank. This tank has such a high dust collection volume that it only needs to be emptied once a year.

1. Vibration-Free Connection Nozzle

To prevent any noise and vibrations from being transmitted to the wall or pipe system, each profivac is equipped with a vibration-free connection nozzle.

2. Dust-Free Dirt Emptying

You’ll never have to inhale 100 times the amount of airborne dust when emptying the dirt tank again, as there’s no longer an obligatory dust cloud during dirt disposal. The dirt tank can be equipped with a conventional 35-liter garbage bag, eliminating any micro-dust in the air during dirt emptying. No follow-up costs.

3. Separate Motor Air Cooling

The electric motors are cooled through the slots in the cover, where clean ambient air is drawn in to evenly cool the motor compartment. Since the suction turbine chamber is completely separate from the motor compartment, the motors are fully protected from the heated intake air, which may contain residual dust. Overheating is thus prevented. This increases the lifespan of the motors by years.

4. Cyclone Separator

The sucked-in air containing fine dust, dirt, and debris is shot into the cyclone filter chamber at over 120 km/h. Through cyclone separation in the round profivac central vacuum cleaner, all the dirt is pressed against the outer wall, rotating downward, and then settles in the air-calmed dirt container.

5. Powder-Coated Steel Housing

The profivac central vacuum cleaner housing is entirely made of steel, chromatid, and powder-coated. All components are grounded to prevent static charge build-up.

6. Control Line Connection

Here, a low-voltage cable for switching on and off can be installed; with WIRELESS, this work can be entirely avoided.

7. Tension Lock

For easy opening and closing of the dirt container.

8. Reset Button

After maintenance is performed, the reset button clears the display on the handle. The device can be manually turned on and off via the reset button on the central unit.

9. Super Sound Insulation 65dB

The sound level is measured at a distance of 1 meter (DIN EN ISO 3744). Profivac meets the increased sound protection requirements according to SIA 181!

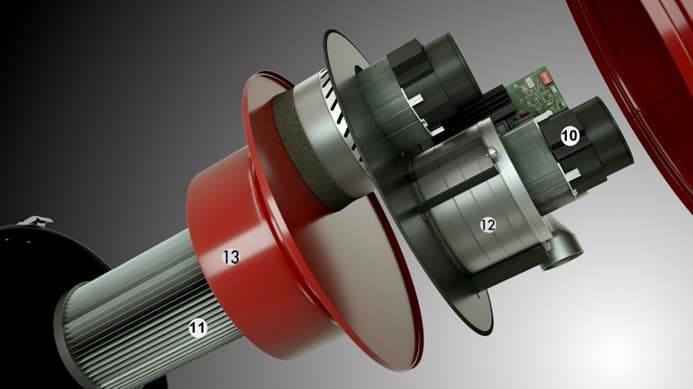

10. Carbon Brushes

Carbon brushes conduct electricity to the motors. These typically need to be replaced every 10-15 years, depending on usage hours. After replacing the carbon brushes, the motors will run smoothly for many more years.

11. The Filter System with No Ongoing Costs

Washable polyester filter (Spunbond fleece). The filter can be easily cleaned by removing the finedust from the lamella. No need to purchase a new filter. Filter of BIA C category, (smaller) 0.2 µm, ZH1/407. Our filter is suitable for clean rooms. Exhaust to the outside can be avoided if the device is installed in a garage or technical room (no heat loss).

12. Bypass Motors

The number one choice for the best suction power! The profivac 430 always features two bypass motors, as used by professionals. With its world-class suction power (vacuum: 45 kPa / 4500 mm water column), you can cut your cleaning time in half – suction power is more than 50% higher than most single-motor central units.

Gentle motor start-up.

The soft start ensures that the motors do not receive full current all at once. The motors are gradually supplied with power. As a result, there is less wear and tear during start-up. This leads to a much longer lifespan for the motors.

Motor overrun

After shutdown, the motors continue to run for about 2 seconds. This ensures that all debris in the pipeline is removed. Practically, no dirt should remain in the way.

Bypass motor technology

Our suction turbines are additionally protected with a bypass, so that the warm air filled with fine dust particles is diverted past the motors. In cheaper, so-called through-flow motors, the contaminated air is blown through the motor, which has an extreme impact on the service life and warranty period. For this reason, we exclusively use bypass motors. This allows us to increase the lifespan of our motors and devices multiple times over.

13. Impact protection system

The filter is equipped with an impact protection system, ensuring that damage to the filter from coarse debris during suction is prevented.